Potassium Fluoroaluminate as a Brazing Flux: How It Powers the Automotive Industry

In modern automotive engineering, lightweight and durable materials are crucial for achieving higher fuel efficiency, lower emissions, and improved performance. Aluminum alloys are among the most widely used materials in the sector because they combine low weight with good mechanical strength and corrosion resistance. However, joining aluminum components is a technical challenge, since aluminum forms a thin oxide layer that resists melting and hinders reliable bonding. This is where potassium fluoroaluminate (KAlF4) comes into play. It acts as a brazing flux, enabling the production of leak-proof, strong, and long-lasting joints in automotive parts.

What Is Potassium Fluoroaluminate?

Potassium fluoroaluminate is a crystalline compound derived from potassium, aluminum, and fluorine. It is typically used in powder or paste form as a flux during aluminum brazing processes. A flux is a material applied to the surfaces to be joined, which removes oxides, lowers the melting point locally, and promotes the flow of filler metal.

Unlike traditional chloride-based fluxes, potassium fluoroaluminate is non-corrosive, has high thermal stability, and does not require post-brazing cleaning in many cases. These properties make it the industry standard in the automotive sector, especially in controlled atmosphere brazing (CAB), where aluminum parts are heated in a furnace under protective nitrogen gas.

Why the Automotive Industry Relies on Aluminum Brazing

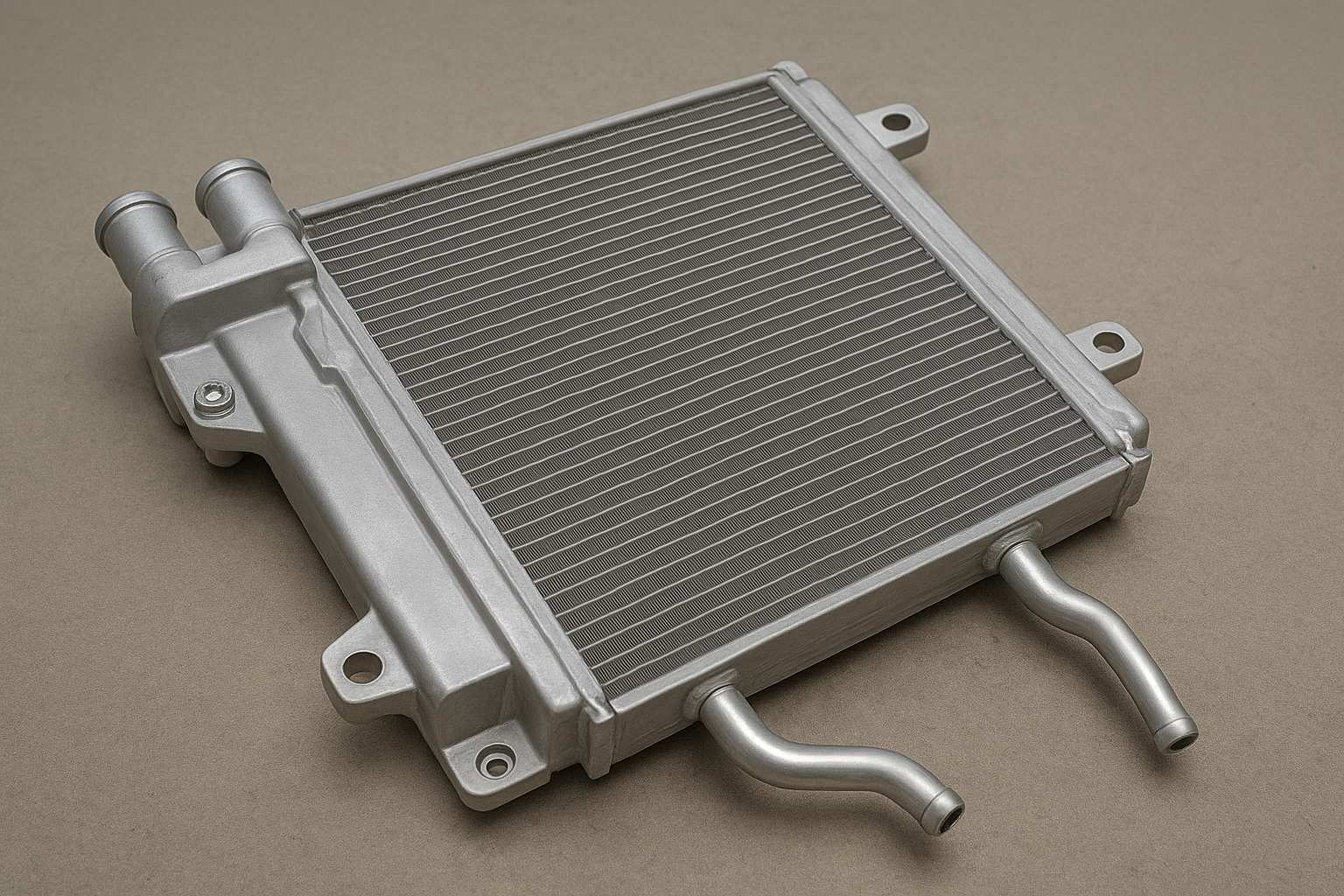

The automotive sector is under constant pressure to reduce vehicle weight while maintaining safety and durability. Aluminum alloys are used in radiators, condensers, evaporators, and charge-air coolers, which are essential components of modern vehicles.

But simply welding aluminum is not always efficient or precise enough, especially when dealing with thin-walled components. Brazing offers:

● Leak-tight joints — essential for heat exchangers that circulate coolant or refrigerant gases.

● High precision — the process ensures uniform connections in complex assemblies.

● Cost efficiency — many components can be brazed simultaneously in a furnace. Potassium fluoroaluminate flux is the enabling agent that makes this brazing possible on a large industrial scale.

How Potassium Fluoroaluminate Works in Brazing

1. Surface Preparation

Before brazing, aluminum surfaces are cleaned and flux is applied. The potassium fluoroaluminate particles adhere to the metal and cover the oxide film.

2. Oxide Removal

As the furnace heats up, the flux becomes active at around 560–600 °C. It dissolves and disrupts the aluminum oxide layer, exposing fresh metallic surfaces.

3. Filler Metal Flow

Once the oxide barrier is removed, the aluminum-silicon filler alloy melts and flows into the joint gaps by capillary action. The flux ensures smooth spreading of the molten filler.

4. Joint Formation

Upon cooling, a strong metallurgical bond forms between the base aluminum and the filler, creating a durable, corrosion-resistant connection.

This chemical and physical interaction is what makes potassium fluoroaluminate irreplaceable in automotive brazing technology.

Applications in the Automotive Industry

1、Heat Exchangers

One of the largest uses of potassium fluoroaluminate flux is in the production of radiators, condensers, and evaporators. These heat exchangers require extremely fine, leak-proof joints to ensure efficient thermal transfer. The flux enables manufacturers to produce thousands of such units daily with high reliability.

2、Air Conditioning Systems

Automotive air conditioning relies on aluminum components that carry refrigerant under pressure. Flux-assisted brazing guarantees the strength and integrity of these parts, preventing leakage and maintaining system performance.

3、Turbocharger and Cooling Modules

Modern cars, especially turbocharged engines, require charge-air coolers and complex cooling modules. Brazing with potassium fluoroaluminate allows thin, lightweight aluminum sheets to be joined securely, reducing overall engine weight while ensuring high heat resistance.

4、Electric Vehicles (EVs)

With the rise of EVs, demand for battery cooling systems and lightweight aluminum structures is increasing. Potassium fluoroaluminate flux ensures high-performance joints in components where thermal management is critical for safety and efficiency.

Environmental and Economic Benefits

● No need for post-cleaning: Unlike chloride fluxes, potassium fluoroaluminate does not leave corrosive residues, reducing both production steps and waste.

● Lower material costs: By enabling reliable brazing of thin aluminum sheets, it reduces overall material usage.

● Energy efficiency: Controlled atmosphere brazing with this flux consumes less energy compared to alternative methods.

● Recyclability: Aluminum parts joined with potassium fluoroaluminate remain recyclable, supporting the circular economy in the automotive industry.

As vehicles continue to evolve toward electrification and higher efficiency, the demand for reliable lightweight materials will only grow. Potassium fluoroaluminate flux will remain at the core of this transformation, ensuring that brazed aluminum parts can meet the increasing performance standards of the automotive industry.